PRODUCTS

COPPER PLATING

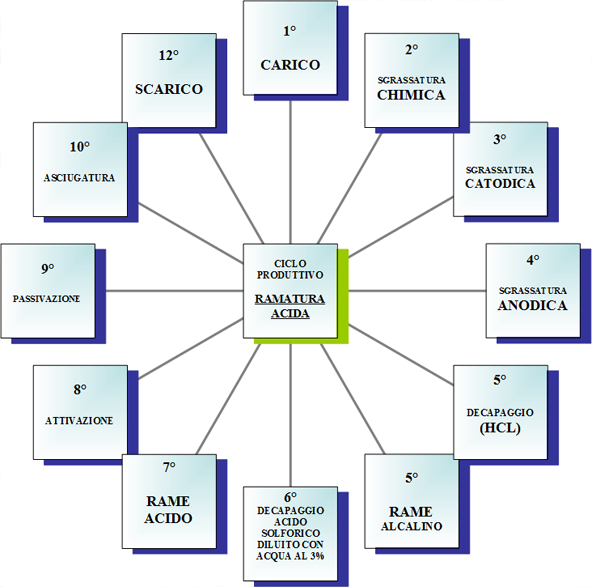

ITER PRODUCTION COMPANY

The iron poles are loaded on special frames and hanging racks of plastic-coated copper which are then transported in the tanks to tanks controlled by software.

DESCRIPTION OF CYCLE

From degreasing chemical, at a temperature of 60 °, roughing passes to the cathode; after roughing anodic to go then in hydrochloric acid in 10% solution.

After this step, the stakes are headed in the alkaline copper bath in which it already sets a first layer of copper before going into the acid copper bath.

Given that the temperature in the tanks of acid copper must be between 25 ° / 28 ° C, the tanks are heated by a steam boiler, when the bathrooms are cool, cooled by a refrigeration unit when they are hot. These baths are composed of sulfuric acid and copper sulfate and should be continuously filtered with pumps cartridge.

The poles are held in the more acid copper bath, the greater thickness.

At the end of the treatment the poles are transported on an activation containing an alkaline substance and then to the passivation and drying.

To the output of the operator unloads the posts from the frame and performs the following operations:

Control of the thickness of the poles according to UNI ISO 2859 part 1

Control of the threads (if any) with their sleeves.

Passage, by means of a sponge, a protective oily for the maintenance of the same (without which the copper would tend to oxidize).