Paint Plant

Area covered 3000mq plus 7000 mq of service area.

Plant features:

L (lenght): 13mt / l (width): 2,5mt / H (height): 3,0mt

max weight 2500Kg

Our paint plant is one of the most important plants on the Italian territory for its dimensions. It is characterized by a total length area of 120 meters and it covers 3000 mq. It benefits of 7000 mq of service area for the in-coming goods deposit.

The painting process is characterized by first quality epoxy powder. The manufacturing is made exclusively on aluminum and metals.

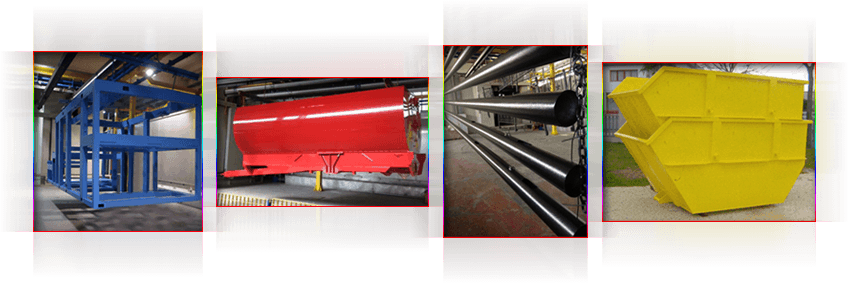

The advanced technological plant is suitable for hulking products i.e. lighting poles, containers, voluminous frameworks and complex and hulking structures.

It includes also equipment for bread production, auto camera, garbage containers, truck hook lifts, fencing and gate accessories, vehicular platforms.

In its painting cabinets, plant can include either very small or big objects till an important weight (maximum 2500 Kg).

Considering the plant high automation, orders with low quantities can be arranged.

The plant characteristics are:

L=13.000mm x l=2.500mm x H=3.000 mm

This kind of painting treatment combined (if requested) to a particular superficial aspect (ashlars or wrinkled) can offer a higher product resistance and duration toward the atmospheric aspects, impacts to whom the product can be exposed.

The used synthetic resins stick to the material thanks to the electrostatic side effects and thanks to its transition in an oven having a temperature of 180° / 200°. They melt and polymerize performing a perfect layer.

The thickness is about 80 / 120 um.

The cycle we perform is subdivided into:

- Phosphor - Pickling paste having PH sensor and heated to 45° C, staying regulation using PLC.

- Rinsing by using water.

- Rinsing by using anti-mineralized water, completely mechanized.

- No wrinkles (without rinsing): a technology able to pre-treat ferrous surfaces, steel, galvanized and aluminum material.

- Static drying oven.

- A painting cabin with an high color change speed.

- Polymerization oven able to check electronically the laying times and execute the four cooking phases grant.

The delivery of the painted material and its packaging is executed by using an internal company instruction rules program subdivided by material code.

We use Pluriball for cylindrical features or textile or cardboard, or Styrofoam for a big variety of products.

If requested we execute also sandblast.

The product delivery can be made by using client means of transportation after agreed with the client.

Reliability, professionalism and price competitively of the product complete our Society Profile.

If required we also do the sanding of the products.

If required we also do the sanding of the products.

Delivery of materials can be done with equity with prior agreement with the customer.

Power coating of:

- Lighting street steel poles

- Lighting accessories

- Arms /brackets for lighting poles

- Head pole for lighting steel poles

- Decorations for steel lighting poles

- Decorative base for lighting poles

- Gates for fence

- Boxes for heavy transport

- Aluminium doors

- Machines for bread production

- Facilities for speed cameras

- Tanks

- Trolleys

- Metal shelving

- HEA/HEB Beams of hight, medium, small flow

- Shelters Parking

- Metal Doors

- Protective fence

- Traffic signal poles

- Frames for structures

- Agricultural machinery

- Metal containers