PRODUCTS

ZINC PLATING

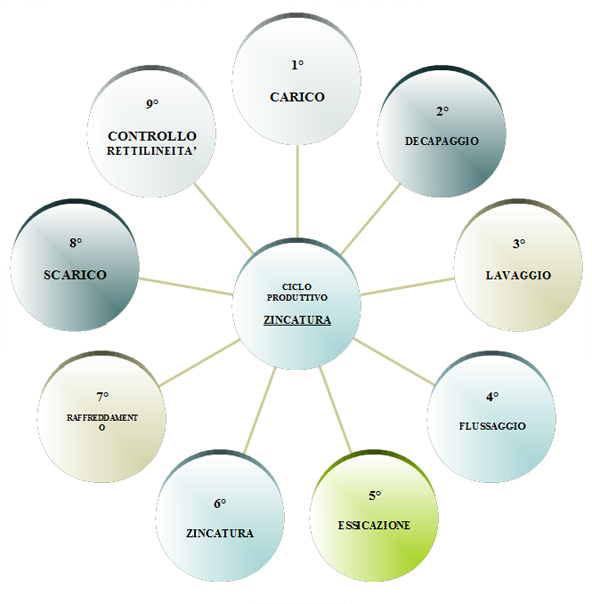

ITER PRODUCTION COMPANY

The iron materials from the warehouse are carried in the cargo area of galvanizing plant, to be here after being hooked to special equipment is lifted with cranes and immersed in tubs of pre-treatment (PICKLING)

These pickling tanks containing a solution of 16% hydrochloric acid (HCL).

The materials are immersed in these tanks for a period of time depending on the oxide present on the surface of the pieces.

After the time necessary to obtain a perfect cleaning, the materials always by means of bridge cranes are extracted from the bath and allowed to drip on the same, and then moved and immersed in the bath (washing or rinsing)

After being extracted from this tank, the materials are moved (always with bridge cranes) towards the last bath and immersed in it.

This tank (FLUSHING) contains an aqueous solution consisting of zinc ammonium chloride, salt dissolved in water (ZnC12 - 2NH4; Contained in ZnC12 = 52/54.6%)

After the extraction of materials and dripping from the tank flushing these are placed in a dryer for drying.

The materials after this last stage are ready to be immersed in the bath of molten zinc content in a steel tank heated by a gas oven methane

The molten zinc at a temperature of 450 ° C and 'type electrolytic 99.5% with the addition of' 1 ° / OO aluminum.

The immersion of materials in molten zinc is by bridge crane, a total immersion of the pieces provides cleaning of the surface of the bath of molten zinc with spatulas manuals, followed by the extraction of the pieces.

After this operation, the materials can be cooled in a bath full of water static, or sent to the area where the exhaust will be stationed until complete cooling.

The cycle described above guarantees a product with characteristics that conform to that specified by the UN EN 40-5 and CEI 7-6

With regard to lighting columns these venvono controlled using the two methods A and B of EN 40-5 inherent straightness with sampling mode shown in item 13.2